- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

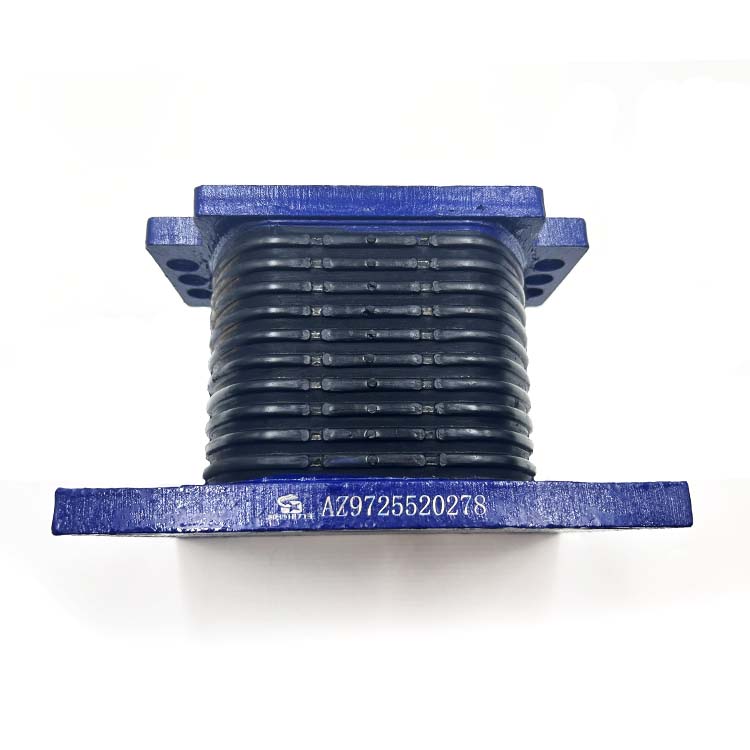

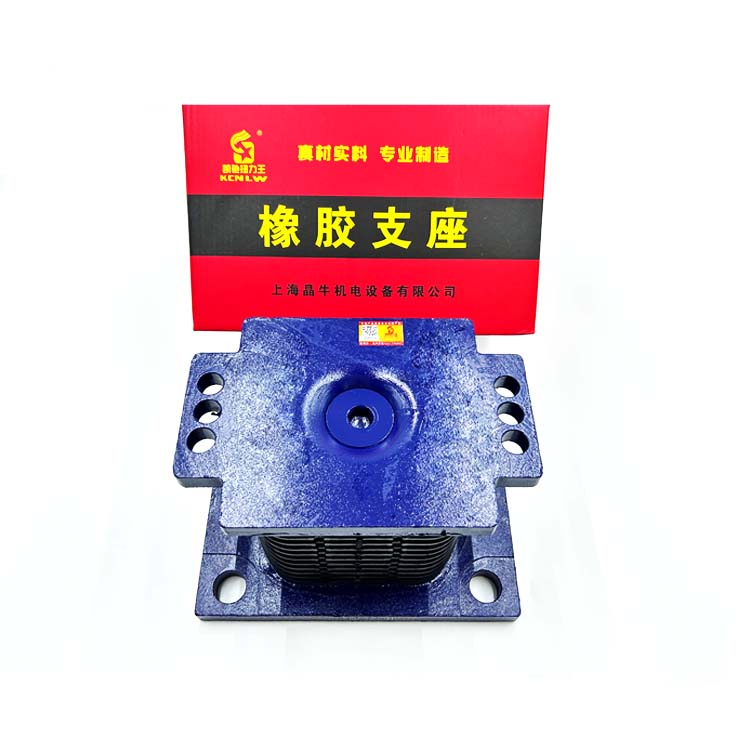

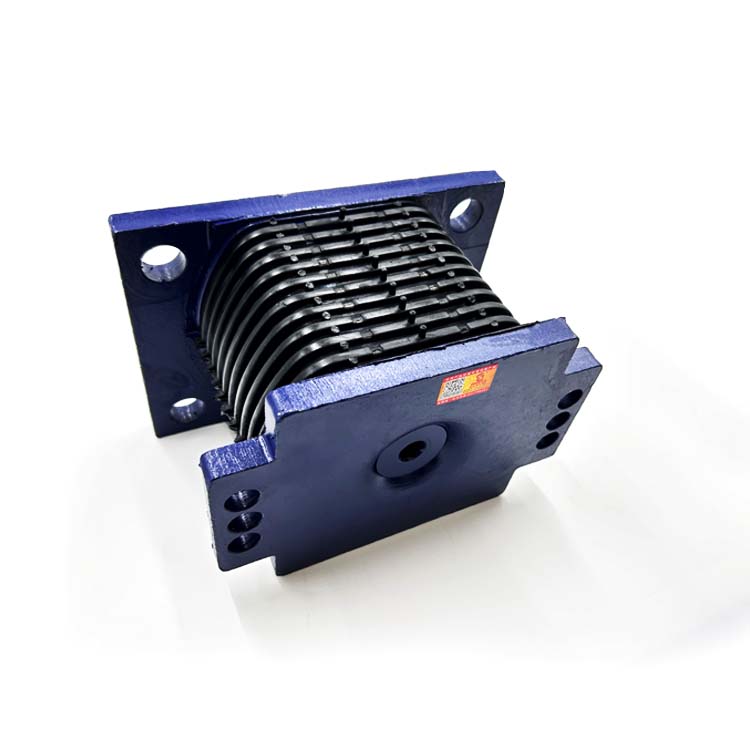

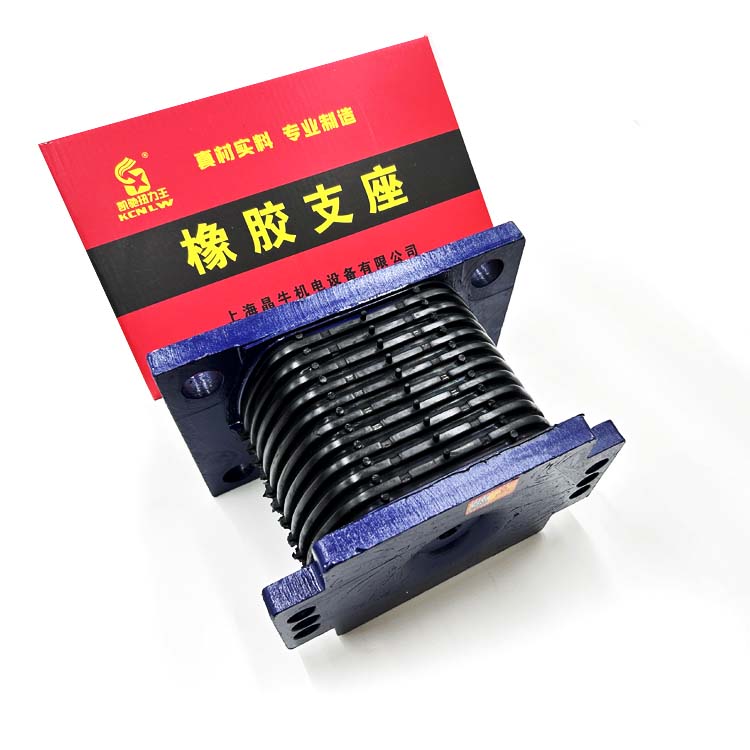

Truck Rubber Leaf Spring Mounting For Truck

Truck Rubber Leaf Spring Mounting For Truck is a bridge bearing product made of multiple layers of natural rubber and thin steel plates inlaid, bonded and vulcanized. This type of rubber bearing has sufficient vertical stiffness to withstand vertical loads and can reliably transmit the pressure of the superstructure to the pier; it has good elasticity to adapt to the rotation of the beam end; it has large shear deformation to satisfy the horizontal displacement of the superstructure.

Model:AZ9631523175

Send Inquiry

Maintain

1) Plate Truck Rubber Leaf Spring Mounting For Truck should be maintained and inspected regularly. Once problems are found, they should be repaired or replaced in time.

2). Plate Truck Rubber Leaf Spring Mounting For Truck and PTFE slide rubber bearings should check the following:

a: Whether there is slippage or hollowing out of the bearing;

b: Whether the shear displacement of the support is too large (the shear angle should not be greater than 35°)

c: Whether the bearing has excessive compression deformation; (the maximum compression deformation shall not exceed 0.07te, te is the total thickness of the rubber layer of the bearing

d: Check whether the rubber protective layer of the bearing has cracking, hardening or other aging phenomena, and record the crack location, crack width and length;

e: Whether the convexity of the rubber plates between the stiffening steel plates on each layer of the support is uniform and normal;

f: For the PTFE slide rubber support, you should check whether the layer of PTFE slide above the support is intact, whether there is any peeling phenomenon, whether the support has slipped out of the stainless steel plate on the top of the support, and whether the 5201-2 silicone grease Apply and fill the reservoir of the PTFE slide rubber bearing.

3) All parts of the support should be kept intact and clean. Remove garbage and debris around the support in time, and remove snow and ice in winter to ensure the normal operation of the support. At the same time, sewage should be cleaned frequently to remove accumulated water on piers and platform caps. Rubber bearings should be prevented from contacting grease. Residual engine oil on the bottom of beams and piers and platform caps should be cleaned. Prevent rubber from aging and deteriorating from losing its function.

2.4.4 If the pressure on the beam fulcrum is uneven and the support is hollow or has excessive compression deformation, it should be adjusted.

2.4.5 Plate Truck Rubber Leaf Spring Mounting For Truck should be replaced in time when excessive shear deformation, aging, cracking, etc. occur. ,

2.4.6 For the rubber support of the PTFE slide plate, if sediment is found to enter the contact surface between the PTFE slide plate and the stainless steel plate or the silicone grease oil dries up, clean it in time and inject new silicone grease oil.

| Model |

AZ9631523175 |

| Name |

Truck Rubber Leaf Spring Mounting For Truck |

|

Material |

High quality material |